Alloy bikes are incredibly popular and this stems largely from their relatively low cost when compared to their carbon, steel and titanium counterparts. But, have you ever looked at the various bikes that are available and wondered just exactly why the frame material makes such a difference to how a bike rides? Read our Aluminium Frame Tech Explained blog to find out why the material matters more than you could ever possibly imagine.

Alloys arrival

Throughout most of the 20th century, Steel was the only option available when it came to building a bicycle frame. The status quo changed somewhat in the 1970s when some weird and wonderful new bikes began to appear on the market. Considerably lighter than their steel counterparts, these futuristic-looking new arrivals created quite the storm in cycling circles. Aluminium had arrived, and its appearance altered the course of cycling forevermore.

These early aluminium prototypes were largely constructed along similar lines to the contemporary steel frames of the era. This rudimentary process consisted of sections of straight gauge tubing being 'glued and screwed' together. The problem with this method was that it did not lend itself to aluminium tubing. The frames produced offered a comfortable ride feel but this comfort came at a cost. Whenever the frame was stressed during sprints or when climbing they had a tendency to flex alarmingly.

Next generation alloy

As these early pioneers of alloy frame design learned from their lessons the next evolution in frame design started to take shape. This generation of alloy frames was also constructed of lightweight straight gauge aluminium tubing. However, advances in the manufacture of aluminium tubing and frame building techniques enabled tubes to be produced of a much larger diameter. The resultant ride feel was very much the complete opposite of those early examples.

Gone was the comfortable but alarmingly flexy ride quality. In its place was a new generation of lightweight aluminium frames that were bone-shakingly stiff. As you can well imagine, this was less than ideal considering the state of disrepair of many roads. It was these earliest examples of aluminium that gave alloy frames a reputation for delivering a harsh ride quality that it has never really shaken off. Even today when refinements in frame tubing manufacture and construction have added compliance to greatly improve the ride quality that they offer.

Left: The iconic Ribble 7005 Audax became synonymous with winter training and cycle commuting. Rare was the winter club ride not feature at least one of these steadfast workhorses. Right: Today's Ribble Gravel AL handcrafted from custom-formed 6061 T6 heat-treated aluminium with meticulously designed tube profiles for a rugged yet lightweight platform with seamlessly smooth welds offering enhanced strength and a premium finish.

Tig Welding

The '80s and '90s saw the major cycling manufacturer's make their first forays into the realm of TIG (Tungsten Inert Gas) welding. TIG welding is a process that utilises 3 component parts;

- a non-consumable tungsten electrode is used to produce the weld.

- Inert shielding gas is prevents contamination.

- A filler material is used to fill the weld.

Due to the extra stresses applied to the welds, most high-quality aluminium frames will have smooth welds (also known as seamless welds) to avoid stress concentration.

Tube Shaping

Due to its low density, aluminium is a relatively simple material to work with. It can easily be shaped to suit different ride disciplines. A typical example would be an alloy TT bike which has oversized airfoil tube profiles to improve aerodynamics. The tube shapes will normally be achieved through hydroforming. A process where a tube 'blank' is placed inside a die. Fluid is then forced through at incredibly high pressure which forces the tubing to assume the shape of the mould it is sat within.

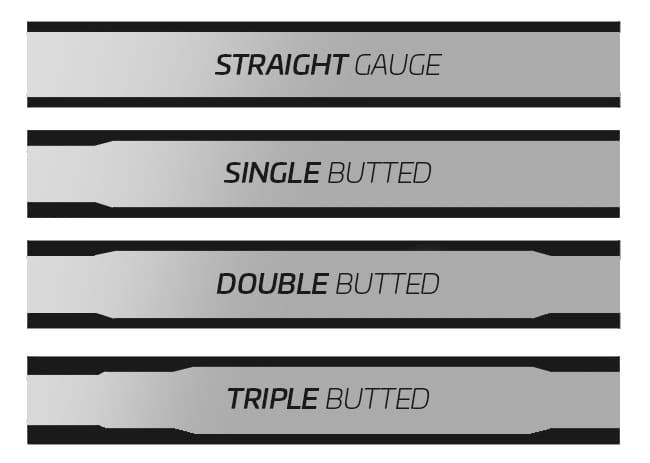

As well as shaping the tube, it is also possible to vary the thickness of the walls of the tubes to improve strength. This process is known as 'butting' and there are 3 standard types of butting.

- Single butted - One end of the tube is thicker for increased strength at the junction with another tube. A prime example would be the seat tube where the majority of the strength is required at the bottom bracket junction.

- Double-butted - The tubes are thicker at each end to provide additional strength at the junctions but thinner in the middle to reduce weight. A frames down tube is most commonly double-butted.

- Triple butted - Tubes will have 3 different wall thicknesses.

Today's Aluminium Frames

Compared to steel, aluminium alloys have a lower density and lower strength. You would, therefore, think that steel would be far superior, right? Well, it's not quite as simple as that. You see, alloys actually have a superior strength to weight ratio. This allows more scope for experimentation with the thickness of the tube walls. The strength of each tube wall can be increased simply by increasing its thickness. Without significantly altering the weight of the frame. The same cannot be said for steel where increasing the wall density significantly increases the overall weight of the frame. The end result is a frame that is much stronger and stiffer whilst also remaining lighter than their contemporary steel counterparts.

A modern alloy frame will commonly have a tube wall thickness twice the diameter of a comparable steel frame. Using twice as much material within its construction and having 20-30% larger tube diameters to provide the required level of stiffness. The most common alloys used in the cycling industry are 6061, 7046 and 7005. Ribble's range of aluminium bikes features 6061 alloy tubing exclusively. In particular, the T6 variant.

The T6 designation refers to the tempering process and contains magnesium and silicon as the major alloying elements. This precipitation-hardened (heat-treated) aluminium alloy has a very high tensile strength which results in a very tough, yet lightweight frame.

The alloy bikes of today remain supremely stiff. However, it is the major advances in materials, frame design, and construction techniques that have produced a range of alloy bikes that offer a compliant ride quality.

Dropped seatstays

One of the most noticeable features of many modern frames is the dropped seat stay geometry. Ribble has adopted this design throughout most of its entire catalogue of alloy bikes. Dropping the stays down the seat tube creates vertical compliance to reduce the effects of road vibrations. In layman's terms, this means that the seat tube and seat post flex. This prevents the vibrations from travelling directly up the tube and reduces rider fatigue.

Modern aluminium bikes like the Endurance AL Disc continue to be as popular today as their forebearers yet are far more comfortable to ride over longer distances.

The incredible story of 2 best friends taking on the Himalayas on the Ribble Adventure 725. Read about it here.

Ribble Cycles were established in1897! Read about the intriguing journey from local bike shop to global bike retailer here.

The CGR family of all-road bikes are exceedingly popular but what difference does the frame material make to the ride quality? Find out here.